By blow moulding, blow mould water tanks can be produced with a variety of shapes and sizes that are not possible with other manufacturing processes. With this technology, tank manufacturers can create an incredible range of products that meet the specific needs of their customers. Topline Industries is a leading water tank manufacturing company that has provided blow moulded water tanks at very affordable prices for many years. We have three, four, and five-layered water tanks that are made of durable materials and are easy to operate. Extrusion blow molding is a technology that makes it easier to produce different layer tanks. Using extrusion blow molding, we can create a variety of shapes and sizes for our tanks without having to use other methods such as injection molding or die casting. This allows us to save money on the manufacturing process and make sure each tank has the perfect shape and size.

Product Specification - Blow Moulded Water Tanks

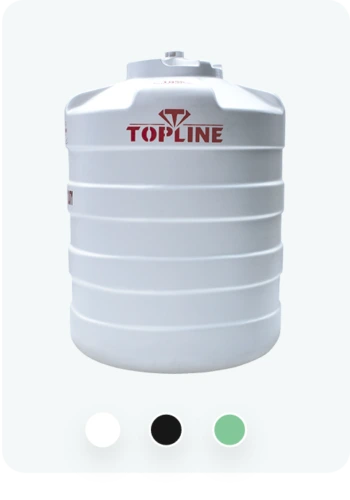

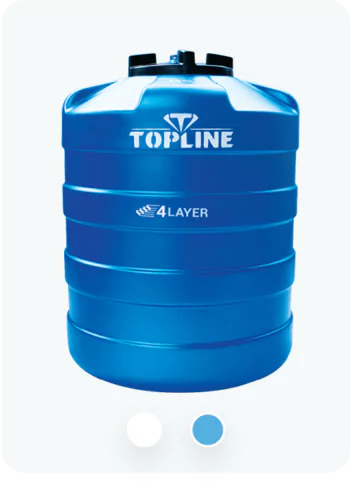

The 3 layer water tanks capacity are - 300ltr,500ltr,750ltr,1000ltr, 2000ltr.They come in green, white and black colour. The 4 layer water tanks capacity are - 300ltr,500ltr,750ltr,1000ltr, 2000ltr.They come in blue and white colour. The 5 layer water tanks capacity are - 300ltr,500ltr,750ltr,1000ltr, 2000ltr.They come in yellow colour.

Product Details - Blow Moulded Water Tanks

Topline Tanks are a type of plastic water tanks that have been specifically designed to be used by plumbers. These tanks are plastic tanks that are made from virgin food grade HDPE material for safe and easy use of potable water. Additional Details

- Topline water storage tank has a surface that is coated with ultra-titanium so that the sunlight reflects more than 90% of it. This helps improve its efficiency in terms of both heat and light absorption, which can result in longer life spans for the coating. This also ensures long-term protection for your tank.

- The tank's insulated features help keep the tank water at normal temperatures even in hot summer months.

- Also, the water vapour which is formed inside the tank is exhausted outside with the help of a cooling lid.

Features & Benefits - Blow Moulded Water Tanks

- These tanks have built-in antimicrobial technology that helps protect against infections caused by bacteria.

- UV-protection helps to prevent the tanks from becoming contaminated and seasonally deteriorated, which can lead to a decrease in their life span and performance.

- Topline blow-moulded water storage tanks have anti-oxidant features that help to prevent irreversible damage to the tank's internals, ensuring long lasting service.

- Topline blow-moulded water storage tanks have a carbon protection feature to prevent wear and tear in the tanks. The high carbon content also makes the tank harder and stronger.

FAQs

- What is blow Mould water tank? - The blow moulding process is used to create blow molding water tank by filling the moulds with plastic and then shaping it into the desired shape with air. By using this particular manufacturing process, mould makers can produce a variety of shapes for water tanks, including round, oval, and square containers.

- Which color is best for water tank? – The blow mold tank is available in different colours like white,black,blue,yellow and green.Topline industries are having all these colours choices in their water tanks.

- Which water tank is best for home? - For domestic purposes, you can use blow molded water tank from Topline Industries. Our tanks can provide utmost safety when it comes to water storage. All our tanks' designs come with titanium coatings and they are UV protected. The construction material is also the best-grade food materials procured from topmost suppliers. Topline industry tanks are designed to meet that need while protecting your environment and people's health.

Rotational moulding is a cost-effective and environment-friendly manufacturing process for producing roto mould water tank. In rotomolding, the plastics are cooked at high temperatures in a hollow mould that is rotated at high speed around two axes. The resulting product has high abrasion and chemical resistance, excellent heat transfer and requires very low maintenance. In order to produce roto mold tank in rotoromolding, raw material polyethylene is heated up to around 180 to 200 °C for a few minutes. This process results in soft plastic made from ethylene, one of the main constituents of petrochemicals.